HIGH STRENGTH STEEL: THE KEY FOR TRANSPORT EFFICIENCY

Team CVF spoke with Sharad Rastogi (Country Manager) and Mr. Joao Preichardt (Specialist – Structural Technology) from SSAB Swedish Steel, who outlined how the use of High Strength Steel can help in light-weighting while at the same time improving strength and performance.

In this episode, Attentive founder and CTO Pedro Araújo talks about what it takes to build a tech new product from the ground up. Discover their approach to running an engineering team, from adopting new open source technologies, to onboarding junior developers and learning .

Q1. SSAB has production facilities in Sweden, Finland and the US. In India, you have a stock warehouse in Bangalore? What are SSAB’s plans for India?

Sharad Rastogi: SSAB has a stock warehouse located in Bangalore and we are increasing the local stocks level to meet the country’s demand. SSAB also has local presence in Bangalore, Mumbai, Delhi & Kolkata to serve our customers. Currently, we plan to continue the import of High strength Steels to be sold in India.

Q2. Majority of Indian market is still cost conscious; whereas for product like yours, total cost of ownership needs to be considered while taking a buying decision. Are you seeing any behavioural shifts from consumer end in the recent past on this front?

Sharad Rastogi: SSAB’s High Strength Steels help cut down on weight and extend the service life in comparison with regular steels. Customers will see a lighter truck/ container made with SSAB’s high strength steels, have an increased load capacity by 10-20%, and at the same time, it reduces the number of trucks on the road, This results in cost savings on fuel and reduces carbon emission. This is a good news for cost-sensitive steel user who wants a performance-oriented end product.

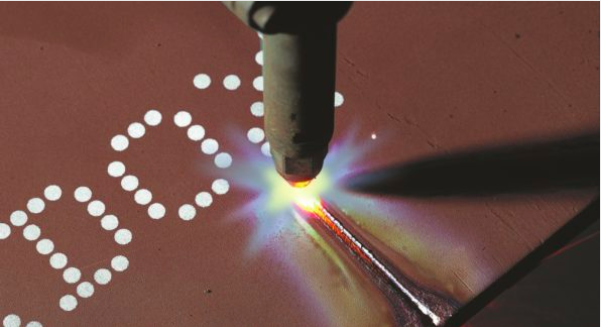

The Indian market has started to realise the importance of high strength steels and its benefits. SSAB’s products, like Hardox wear plate, one of the popular high strength steel, delivers a unique combination of hardness and toughness and this has opened up more new and innovative ways for our customers to design their products that offer extreme performance. SSAB’s steels are also 100% recyclable into new and strong energy-saving products when it reaches its material final expiration date.

Q3. With full frontal crash tests becoming mandatory for commercial vehicles with less than a 1500kg gross weight from 1st October 2018. How is SSAB poised to facilitate the needs of OEMs?

Sharad Rastogi: One of SSAB’s High strength steel materials –Docol, the automotive steel is a trusted partner in the automotive industry. It delivers products and services that makes vehicles safer and more eco-friendly. SSAB’s Docol also provides many steel grades according to VDA and OEM standards.

SSAB’s Advanced High Strength Steels (AHSS) help to reduce weight and provide a higher performance during crash tests.

Q4. SSAB works with its customer with very hand in glove approach – providing technical support, working on design and processing of the steel and also collaborate with them on the development of new material. How is this philosophy of customer centricity providing an edge to SSAB? Can you please share few examples.

Sharad Rastogi: SSAB’s business model is built on fostering close, long-term customer relationships. SSAB continuously develops new products, applications, services and processes in order to constantly enhance our market offerings. SSAB works directly with OEMs, manufacturers and subcontractors through our own sales force and support our customers in developing better and more competitive products. We help them to increase productivity and thereby to reduce costs.

To remain at the forefront in the industry, SSAB also continues to invest in research and development, technical customer support and joint innovation initiatives to get the most out of SSAB’s high-strength and advanced high-strength steels. At the same time, the organization strives towards the highest standards in terms of product quality, shorter lead times and delivery reliability.

With an extensive network of local service centers, SSAB provides prefabrication and steel processing services so customers can focus on their core business. Our service centers can supply slit coil, cut-to-length plate and other formats according to customer specifications. This is how we help our customers to improve their production efficiency, cut material waste and improve end product quality.

SSAB Shape also combines premium steel products with engineering and processing services offered through our own Shape Centers and a worldwide network of processing partners. SSAB’s customer includes Volvo, JCB, Komatsu, Hyundai, and others.

In terms of our India experience, please click on below press release to see how SSAB Shape helps Scania boost competitiveness in India

Q5. Give us a sneak peek into what you’ll be presenting at CVF 2018 (taking place on 26 April 2018 at The Westin – Pune)?

Joao Preichardt: SSAB will present the following topics:

1) Ultra-High Strength Steels – Dealing with fatigue strength limits to develop the new generation of chassis.

2) A compilation of new technologies and design solutions that can be applied together with new steels grades in order to develop the new generation of trailer chassis.

Trailers manufacturers producing chassis, bodies and all sorts of road transport equipment throughout the world have transport efficiency as their main target. Globally, transportation companies are looking for smart and lightweight equipment for efficient transport of payload and not the weight of heavy equipment. Upgrading steel structures in the vehicles from conventional, mild steel to high strength steel has proven to be an effective strategy to achieve such solutions. Now vehicle manufacturers are looking to the next level of upgrading by introducing ultra-high strength steel with yield strength above 700 MPa to develop even lighter and stronger structures.

Q6. What is your expectation from CV forum and what do you plan to achieve there?

Joao Preichardt: The main expectation is to know how local companies are working to increase the efficiency of transport equipment, since regulations about emissions, fuel consumption and weight limits on the roads are becoming tighter. On the other hand, the open market allows customers to look for equipment’s which are a global offering and not local.